- Our patented PFA*-fused ball resists corrosion better than balls made with unprotected metal surfaces. (Refer to any manufacturer’s chemical resistance guide for further information.)

- PFA inhibits the buildup of lime, calcium, sludge, etc. that accumulates on a ball’s surface and prevents premature failure of the valve seats.

- 4000 Series valves with PFA-fused balls can last up to ten times longer than valves made with unprotected ball surfaces.

- The lubricity of the PFA-fused ball allows for lower torque ratings in any application, and eliminates ball pitting, prevents buildup, lowers torque, and stops premature valve failure.

- Since PFA is actually impregnated .008” into the solid metal, it can’t wear, chip, or flake off.

- Same flanges and end-to-end dimensions as any 125# or 150# gate, ball, or plug valve

- Convenience of quarter-turn operation.

- Certified to NSF 61 & 372 for potable water.

- Polyester powder coating for added strength and lubricity.

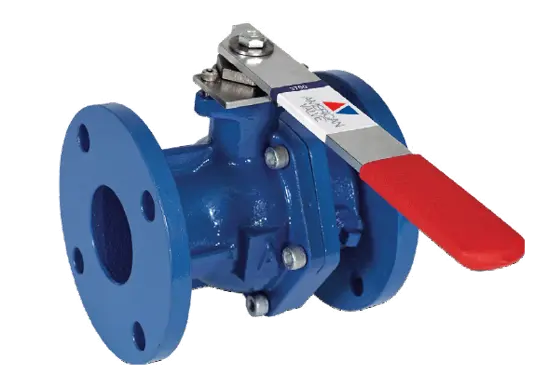

4000 Series Industrial & Commercial Valves

4000 Series Valves Lead the Way

American Valve’s 4000 Series™ is a solution without compromise for facility, factory, and municipal managers. Featuring a patented, corrosion-resistant PFA*-fused solid ball, the 4000 Series is more durable, less susceptible to buildup, and longer-lasting than any ordinary ball valve.

Our design provides maximum flow rate free from obstruction and is the ideal alternative to gate, butterfly, and eccentric plug valves. Seats are protected from wear, and automation is a breeze with low operating torque and an ISO standard mounting pad.

With the same ANSI B16.10 end-to-end dimensions as any 125/150 class gate valve or eccentric plug valve, and the convenience of a quarter turn operation, 4000 Series ball valves are used in a wide range of applications around the world. When gate, butterfly, or eccentric plug valves cannot be trusted, switch to solutions from American Valve.

Commercial & Industrial Valves:4000 Series Product List

Quote List

No products in the list

4000 Series Industrial Valve Features

For facility, factory, and municipal managers who are frustrated with corrosion & build-up on their gate, plug, ball, or butterfly valve and not getting bubble-tight shutoff with their gate or plug valves, the American Valve 4000 Series offers a complete family of cost-effective flanged ball valves featuring a patented PFA*-fused ball that outperforms and outlasts ordinary ball valves.

4000 Series valves are easy to open, easy to close, and feature a patented PFA*-fused ball that resists buildup and corrosion to extend valve life. All 4000 Series ball valves are certified by UL to meet NSF/ANSI Standards 61 and 372 for drinking water safety.

Gate valves have been around for centuries, and so have their inherent design flaws. The metal seat rings and discs are constantly exposed to buildup and wear, making them difficult or impossible to cycle. Earlier ball valves were designed for oil refineries, and lacked features needed in water, air, or steam applications.

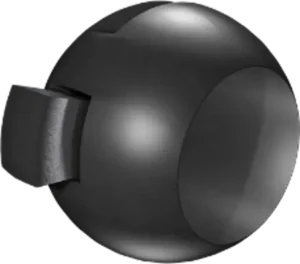

The Ball

The heart of the 4000 Series is in the ball. Whether using a cast iron ball (for cast iron bodies), or a stainless steel ball (for ductile iron and stainless steel bodies), the 4000 Series uses a ball fused with PFA* that resists surface build-up that prematurely damages the seats. Since the PFA* is fused .008” into the solid metal, it can’t wear, chip or flake off.

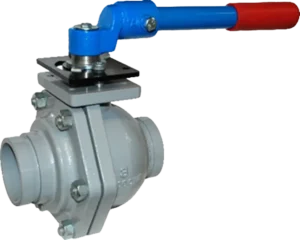

Easy Installation

The 4000 Series has the same end-to-end flanged dimensions of any 125/150 class gate, ball or plug valve—making the 4000 Series the optimal choice for both new and retrofit projects.

Certified for Drinking Water Systems

All 4000 Series valves are certified by Underwriters Laboratories (UL) to NSF/ANSI Standards 61 and 372 in both hot and cold applications.

Seats

4000 Series valve seats are made from reinforced Teflon®, with a back ring for low pressure applications. Compared to a traditional gate valve with a Class IV allowable leak rate, the 4000 Series has a bubble-tight shutoff.

Body Coating

Both the interior and exterior of the body is coated with a Polyester powder coat that meets FDA food-grade requirements.

Top Works

The 4000 Series handle is standard A53 steel pipe, and can be easily removed, replaced, or modified. The valve is lockable in the open or closed position. A square nut can be installed for underground or in-vault installations. It’s easy to accessorize with gear, chainwheel, pneumatic, and electric actuators.

4000 Series Commercial Valves Compared to Competitors

| Feature | 4000 Series Valves | Traditional Commercial Valves |

|---|---|---|

| Valve Replacement Capability | Replaces gate, butterfly, or eccentric plug valves | Limited to specific types |

| Corrosion Resistance | More corrosion-resistant with PFA-fused balls | Less resistant; prone to corrision |

| Buildup Inhibition | Inhibits buildup of lime, calcium, sludge | Prone to buildup, leading to premature failure |

| Durability | Up to ten times longer lifespan | Shorter lifespan due to unprotected surfaces |

| Torque Requirements | Lower torque ratings; eliminates ball pitting and buildup | Higher torque requirements; susceptible to pitting and buildup |

| Wear Resistance | PFA impregnated into metal, preventing wear, chipping, flaking | More susceptible to wear and damage |

| Installation Ease | Same end-to-end dimensions for easy installation | May require modifications for installation |

| Operational Convenience | Quarter turn valve handle lowers torque | Traditional handles may not lower torque |

| Suitability for Portable Water | Engineered lead-free | May not be lead-free |

| Strength and Lubricity | Polyester powder coating adds strength and lubricity | Less durable coatings or unprotected |

| Automation Ease | Engineered for easy automation | Not specifically designed for automation |

Industry Applications for the 4000 Series

American Valve’s 4000 Series can be used in a wide range of industries, including:

Healthcare Facilities

Ensure water safety and reliability in healthcare with American Valve’s NSF 61 & 372-certified valves. Offering zero maintenance and consistent water quality, our valves keep your facility operational without interruptions.

Water & Wastewater Treatment Plants

Prevent breakdowns and reduce costs in water treatment with American Valve’s specialized solutions. Our valves ensure efficient, reliable, and safe operations, optimizing wastewater management and compliance.

Food & Beverage Production

Guarantee water purity in food and beverage production with UL-certified 4000 Series valves to NSF 61 & 372 standards. American Valve enhances product safety and consistency, ensuring top-quality manufacturing.

Automotive Manufacturing

Maintain uninterrupted production in automotive manufacturing with our 4000 Series valves. Designed to prevent breakdowns and support efficient operations, our valves are essential for water and compressed air processes.

4000 Series Valve FAQs

What sets the 4000 Series apart from ordinary ball valves?

What accessories complement the 4000 Series?

American Valve offers a complete package of pneumatic and electric actuators, gear operators, and stem extensions for the 4000 Series. The flexible, modular design of the patented 4000 Series can be used to combine actuators, solenoid valves, limit switches, and other accessories in a variety of applications. Standard 2” square operating nuts are available to effectively satisfy underground requirements.

Is the 4000 Series designed for automation?

The unmatched lubricity of PFA makes the 4000 Series easier and more economical to automate than traditional valves. Our in-house automation program provides a fast, cost-effective, and turn-key solution for your automation needs. Pneumatic and electric actuators made for the 4000 Series have an unmatched cycle life and are the industry-wide preference for even the most severe applications. These actuators offer adaptability to a variety of process conditions to accommodate your application.

How does 4000 Series compare to a gate valve?

- Quarter turn provides instant shutoff.

- Full unobstructed opening provides superior flow rate and durability.

- Easy to open and close, no cheater bar required.

- Class VI positive shutoff.

- No bronze seat rings, bronze disc rings or bronze stems to wear out.

- Lighter than a gate valve, making installation and handling easier.

- Handle shows whether open or closed.

- Ball wipes clean during opening and closing.

- Compact design fits into areas of limited space.

- Throttling is permitted. Top works feature a standard memory stop.

- Low profile design enables easier storage and shipping.

- Can be locked in either an open or closed position.

- PFA-fused ball resists corrosion, in a wider range of applications.

- Zero wear rate in the open position.

- Easy and inexpensive to rebuild/repair.

How does 4000 Series compare to a butterfly valve?

- No disc in the waterway to create turbulence.

- Same ANSI flanged dimensions as gate valve for easier retrofit.

- PTFE seats, not Buna N or EPDM.

- More suitable for steam, petroleum, and corrosive applications.

- Seats are protected from wear in the open or closed position.

- Adjustable PTFE packing instead of O-ring stem seals.

- Class VI positive shutoff.

- Blow-out proof stainless steel stem.

How does 4000 Series compare to a plug valve?

- Full unobstructed flow.

- No exposed internal components to catch and retain debris.

- No lubrication required to ensure smooth operation and maintain seals.

- Lower torque for more efficient and cost effective automation.

- Class VI positive shutoff.

How much torque does it take to turn?

Our patented PFA-fused ball means reduced operating torque compared with ordinary ball valves. The actual amount of torque required to operate a valve is dependent upon many variables, such as line pressure, temperature, type of fluid, and frequency of operation.

*PFA is an ingredient commonly branded as Teflon(R).